Mechanisation in the SA Apple Industry

Like all agricultural industries, mechanisation of SA’s apple industry has evolved through a series of stages moving from hand tools to horses, then to engine powered equipment and tractors, and finally to the highly mechanised orchard systems we know today. Developing technology has transformed apple orchard systems from widely spaced trees reliant on natural rainfall to today’s high density irrigated trellis systems.

This mechanisation section highlights a series of key pieces of technology that have transformed SA’s apple industry:

Soil and Orchard Floor Management

Through the 1800s, initial clearing land for orchards and tilling soil for weed control was achieved using forks, hoes and other hand tools. Trewhella jacks were an important tool for grubbing large tree stumps. Later horses for ploughing and cultivating reduced the labour input. Fertilizer and manures were also hand spread and incorporated into the soil during hand cultivation.

By the 1920s and 1930s, walk behind petrol powered rotary hoes reduced the back breaking work of hand digging, especially on steeper slopes.

Through the 1920s to the 1940s tractors began to replace horses as the motive power for ploughing, cultivating and other orchard operations. Introduction of hydraulic implement lifting systems on tractors after WW2 saw widespread adoption of tractor mounted tillage equipment through the 1950s and 1960s.

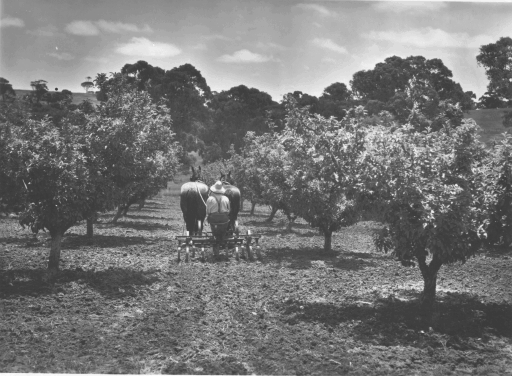

Caption: Apple orchard cultivation with horses – Blackwood 1930’s

Photo No. 106648

History of Agriculture, PIRSA

Crawler tractors were popular from the 1930s through to the 1970s for their ability to work on steep slopes and provide traction under wet conditions. Since the 1970s 4 wheel drive tractors have become popular, and today many apple growers use special low profile 4WD orchard tractors. Changes from kerosene to petrol then to diesel along with improved engine design have given dramatic improvements in power and work capacity.

Caption: Contour planting of orchards at Blackwood in 1950s

Photo No. 106620

History of Agriculture, PIRSA

Frequent tillage of soil resulted in significant erosion. While contour planting was demonstrated to be effective, it was not embraced by orchardists as an erosion control measure. Improved irrigation systems and tractor mounted mowers enabled adoption of grass based orchard floor management systems from the 1960s. These not only reduced erosion, but resulted in improved tree health, pest management, greater yields and improved quality.

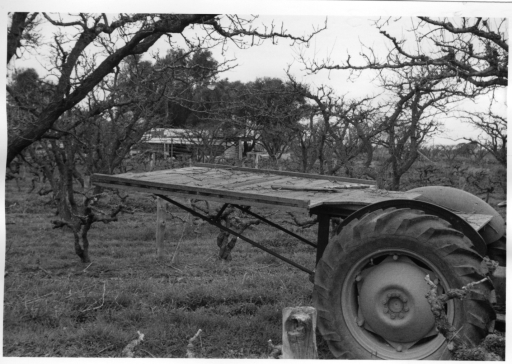

Caption: Early model offset slasher in Lenswood apple orchard 1971

Photo No. 104805

History of Agriculture, PIRSA

Further reading

Wishart R.L.; (1957) Soil Management in Non Irrigated Orchards and Vineyards; Bulletin No 444 South Australian Department of Agriculture

Beare J.A.; (1957) Contour Planting Protects Orchards and Vineyards; Bulletin No 1957/448 South Australian Department of Agriculture

Irrigation

Most early apple orchards were highly reliant on natural rainfall, with resultant variable yields. However, as technology became available, water was sourced from dams and underground aquifers to irrigate trees. Bore pump technology changed dramatically from early beam pumps (pre 1940s) to higher flow and deeper turbine (1950s to 1970s) and submersible pumps (1980’s onwards).

Irrigation became more common during the 1920s and 1930s as petrol powered centrifugal pumps enabled pressure distribution of water from dams and tanks to trees by hand shift moveable pipes with sprinklers. As electricity became more widely distributed, pumps were switched to electric motors.

Caption: Hand shift sprinkler lines in the 1950s

Lighter weight aluminum hand shift pipes became more common during the 1950s and 1960s. Hand shift irrigation lines required a lot of labour, and these were replaced by permanent under tree sprinklers from the 1970s onwards. Despite pioneering work on trickle (drip) irrigation with apples by Fergus Black of the Victorian Department of Agriculture, which showed that trees with split root systems could thrive if only one portion of the roots were watered, this technique has never gained wide acceptance in South Australian apple orchards, mainly because there are benefits in maintaining a growing grass sod between the tree rows both to keep orchards cool and to minimize surface erosion from bare soil. This is achieved most easily with sprinklers. Today, sophisticated electronic soil moisture monitoring systems are used to more accurately match water application rates to tree requirements.

Caption: Apples under drip irrigation at Lenswood Research Centre 1974

Photo No. 104695

History of Agriculture, PIRSA

Further reading

Arndt F.R. (1935). Irrigation Drainage Bulletin No 303 South Australian Department of Agriculture

Armstrong F.W. & Cole P.J. (1977). Drip Irrigation, Bulletin No 77/2 South Australian Department of Agriculture

Pest & Disease Management/Spraying

The major apple pest codling moth first appeared in Tasmania in the 1850’s and gradually spread to all other states except WA. In order to successfully grow apples, orchardists had to effectively control codling moth and a range of other pests and diseases. Lead arsenate was a common early insecticide.

First sprayers consisted of a 10 gallon drum carried by two men, one to operate the hand pump, the other to spray the tree. These were followed by horse drawn wooden spray vats, initially with hand pumps, and later petrol powered pressure pumps. The best 1930s technology was a central vat and pressure pump with spray being delivered through the orchard by galvanized pipes with take off points for hand spraying trees. Tractors enabled development of drive by sprayers with the pump driven from the power take-off of the tractor.

Caption: The first Okanagan turbo mist sprayer imported into Australia in 1951

A spraying revolution occurred in the 1950s with the Department of Agriculture importing the first Okanagan air blast concentrate sprayer from British Columbia, Canada in 1951. While these air blast sprayers gave improved coverage of trees, their introduction was driven by shortages of orchard labour. Using an air blast sprayer, a man could spray 8 to 10 acres per day compared to about 1 acre for hand spraying. Two local companies were licensed to manufacture air blast sprayers, and by 1955 they were in widespread use in the apple industry. Improved sprayer nozzle design and the move from brass to stainless steel, ceramics and plastic nozzles has greatly improved performance and reliability.

From the 1950s to the 1990s, the Dept of Agriculture published annual tree spraying guides and spray compatibility charts in various booklet and poster forms. These were widely used by growers to assist with selection of the most effective pest and disease control measures.

Today the SA apple industry is far less reliant on chemicals for pest and disease control. Improved technology for predicting disease infection periods and the use of integrated pest management systems in conjunction with soft chemicals has greatly reduced chemical use.

Further reading

Steed J.N. (1961); Effective spraying = sprayer care + spraying care South Australian Department of Agriculture Journal of Agriculture October 1961

Tree Management

For more than 150 years, SA apple growers used vase trained trees pruned by hand using secateurs and saws. Pneumatic secateurs and power saws took some of the hard work out of this process.

Caption: Early model picking and pruning platform – 1965.

Climbing ladders have been partially replaced by motorized picking platforms.

However the introduction of high density trellised apple orchards has enabled some mechanized pruning and fruit harvesting.

High density trellised orchards were reliant on use of dwarfing root stocks for different varieties. A series of national demonstration trials were established at Lenswood Research Centre in the late 1980’s to evaluate various variety X rootstock combinations.

Fruit Handling

Early picking of fruit was into buckets on a waist belt, with these being replaced later by canvas picking bags. Fruit was placed into wooden cases (often second hand petrol or kerosene tin cases) and hauled from the orchard on horse drawn sleds or carts.

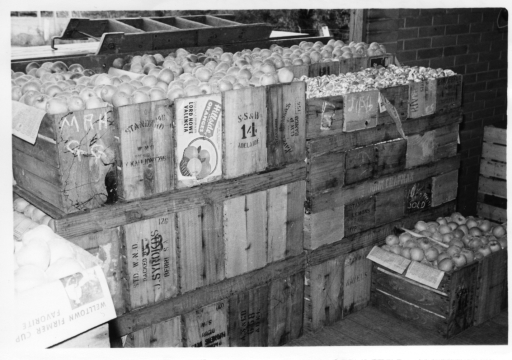

Caption: Bushel boxes of apples for local marketing – 1960s.

Photo No. 103408

History of Agriculture, PIRSA

Transport to market was in wooden bushel boxes via horse drawn drays, and later motor vehicles. Fruit was size graded by eye, and hand wrapped in paper before being packed into the wooden box. Wood wool was sometimes used as a packing material in the box, especially for export.

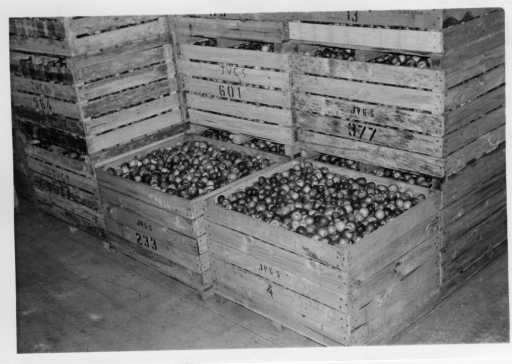

Caption: Bulk bins of apples in cool storage 1966

Photo No. 103390

History of Agriculture, PIRSA

The wooden box was used for handling and storing apples until the introduction of forklifts after WW2. These enabled 20 bushel wooden bulk bins to be handled at cooperative packing sheds and cool store facilities, offering significant labour savings. Pickers were able to empty picking bags into bins carried on trailers. In the 1960s the advent of tractor mounted forklifts enabled widespread field handling of 500 kg wooden bulk bins. Plastic bins are gradually replacing wooden bins.

Packaging for apples has been through a revolution. Wooden bushel boxes were replaced by wooden wire bound boxes and ultimately palletised handling of cardboard cartons. Plastic returnable crates have been important for local marketing since the 1970s.

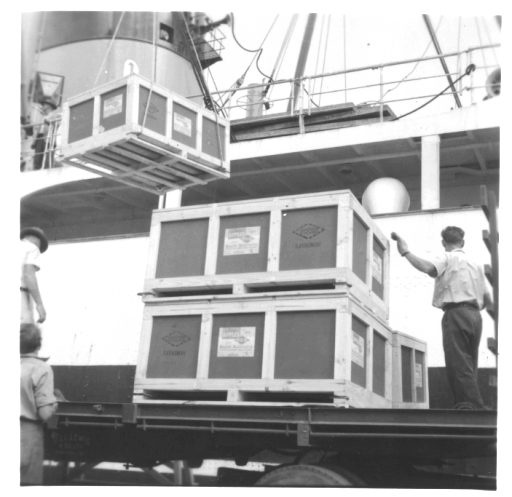

Caption: Trial loading of export bulk bins of Cleopatra apples at Port Adelaide March 1967.

Photo No. 103393

History of Agriculture, PIRSA

Department of Agriculture packing shed advisers played an important role in the 1950s and 1960s developing fruit packing configurations and training packing line staff.

The following link shows a leaflet produced by the Department of Agriculture with the packing instructions and an explanation of packing terms.

Packing Apples in the Australian Apple Box (Dump Bushel) c1950s by H.D. Bain ()

Packing sheds gradually moved from hand grading and packing to use of conveyor belts and mechanical fruit grading. In recent years, introduction of electronic sorting (for colour and blemish) and grading machines has improved labour efficiency of packing sheds and improved the accuracy of fruit packing.